And now a little history, and everything in order:

Build a windmill - my old dream, but there were many obstacles. He lived in a city apartment, but there was no summer house. That is moving from one city to another, then to the third. I have been living in Svetlovodsk for the past 18 years. It has all the conditions - a private cottage for two families, 5 acres of vegetable garden and the same amount of garden. From the east and south open terrain, from the north and west the relief is higher than mine. Winds do not pamper, i.e. not very strong. Well, I think here I will build a windmill for the soul.

But when I took up close contact, it turned out to be not so simple. I did not find a suitable literature. For a long time I could not decide on the generator, I did not know how to make the blades correctly, which gearbox to use, how to protect from a hurricane, etc. As they say, cooked in its own juice. But I knew that if you really want to, then everything will work out. Slowly did the mast. On the chermet, I picked up suitable pieces of pipes, starting with a diameter of 325 mm by 1.5 m in length (to fit in the trunk of my car). In exchange, I handed over scrap metal. The mast turned out to be 12m long. For the foundation, I brought a defective foundation block from a high-voltage support. He buried it 2 meters in the ground and 1m remained above the ground. Then he scalded it with two belts from the corner, welded brackets to them. At the ends of the brackets to the anchor bolts I welded “plates” of 16 mm of iron measuring 50 x 50 cm, interconnected by powerful loops. I bought soft 10 mm cables and lanyards on the market, everything is anodized, does not rust. Welded and buried the anchor under a removable winch. The winch also had to be made home-made, using a ready-made worm gear. In addition, he installed a U-shaped support with a height of about 2 m, on which the mast should lie. Since there was nowhere to hurry - the mast was made without haste and therefore, in my opinion, it turned out beautiful and reliable.

I decided to build a working smaller model to give up to 1 ampere on a 12-volt battery.

For the manufacture of the rotor bought 24 pcs. disk neodymium magnet 20x5 mm I found the hub from the wheel of the walk-behind tractor, according to my drawings, the turner has carved two steel disks with a diameter of 105 mm and a thickness of 5 mm, an expansion sleeve 15 mm thick and a shaft. I stuck it onto the discs and filled in half of the epoxy with magnets of 12 pcs each, alternating their polarity.

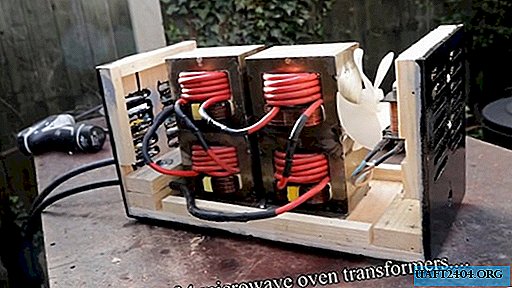

For the manufacture of the stator, I wound 12 coils with enameled wire with a diameter of 0.5 mm, 60 turns per coil (I took the wire from the demagnetization loop of an old worthless color picture tube, there is enough of it). Unsoldered coils sequentially end to end, beginning to beginning, etc. It turned out one phase (I was afraid that there would be a little stress). I sawed a mold from 4 mm plywood and rubbed it with wax.

It is a pity, the entire form assembly has not been preserved. I put waxed paper on the bottom base (stole the wives in the kitchen, she makes pastries on it), put a form on it with a round in the center. Then he cut two mugs from fiberglass. One laid on wax paper the bottom base of the mold. He laid soldered coils on it. He laid the conclusions from the stranded insulated wire in shallow grooves cut by a hacksaw. Filled it all with epoxy. I waited about an hour for all the air bubbles to come out, and the epoxy spread evenly throughout the mold and saturate the coils, refilled where necessary, and covered with a second glass cloth circle. I put a second sheet of waxed paper on top and pressed it with the upper base (a piece of chipboard). The main thing is that both bases are strictly flat. In the morning, I disconnected the form and removed a beautiful transparent stator 4 mm thick.

It’s a pity that an epoxy is not suitable for a more powerful windmill, because afraid of high temperature.

I inserted 2 bearings into the hub, in them a shaft with a key, on the shaft the first rotor disk with magnets glued and half-filled with epoxy, then a 15 mm thick spacer sleeve. The thickness of the stator with flooded coils 4mm, the thickness of the magnets 5mm, total 5 + 4 + 5 = 14mm. On the rotor discs there are left sides at the edges of 0.5 mm to support the magnets with centrifugal force (just in case). Therefore, subtract 1mm. 13mm left. At the gaps remains 1mm. Therefore, the spacer is 15mm. Then the stator (a transparent disk with coils), which is attached to the hub with three copper 5 mm bolts, can be seen in the photo. After the second rotor disk is placed, which abuts against the spacer sleeve. You need to be careful that the finger does not fall under the magnets - it hurts very painfully. (Opposite magnets on the discs must have different polarity, i.e. be attracted.)

The gaps between the magnets and the stator are regulated by copper nuts located on copper bolts on both sides of the hub.

A propeller is put on the remaining protruding part of the shaft with a key, which is pressed through the washer (and, if necessary, the bushing) and the grover with the nut against the rotor. It is advisable to close the nut with a fairing (I never made it).

But he made a roof-visor over the rotor and stator, sawing an aluminum saucepan so as to capture part of the bottom and part of the side wall.

The propeller made a meter piece of duralumin irrigation pipe with a diameter of 220 mm and a wall thickness of 2.5 mm.

I just drew a two-bladed propeller on it and sawed it with an electric jigsaw. (From the same piece I also sawed three blades 1 m long for a wind turbine on a self-generated generator, and as you can see, it remains). I rounded the front edge of the blades “by eye” with a radius equal to half the thickness of the duralumin, and I sharpened the outer edge with a bevel of approximately 1 cm at the ends and up to 3 cm to the center.

In the center of the propeller, I first drilled a 1mm hole with a drill for balancing. You can balance it right on the drill by putting the drill on the table, or hang it on a thread from the ceiling. Balance must be very carefully. I separately balanced the rotor discs and separately the propeller. Indeed, the speed reaches 1,500 rpm.

Since there is no magnetic sticking, the propeller merrily rotates from the slightest breeze, which you do not even feel on the ground. With a working wind, it develops high revolutions, I have an ammeter for 2A direct connection, so it often surpasses a 12-volt old car battery. True, the tail begins to fold and rise upwards, i.e. automatic protection against strong winds and excessive revolutions is triggered.

Protection is based on the inclined axis of rotation of the tail.

The deviation of the axis is 18-20 degrees from the vertical.

This windmill worked for me for 3 months. Removed, disassembled - the bearings are in order, the stator is also intact. The magnets were slightly rusted in places where paint did not get. The cable goes directly without a current collector. I have it done, but I changed my mind about putting it. When the small windmill was dismantled, it was not twisted. So I was convinced that he was not needed, only extra trouble. He gave out up to 30 watts of power. Noise from the propeller is not heard when the windows are closed. And when you’re open, you don’t hear much, if a healthy dream doesn’t wake you up, especially against the background of the noise of the wind itself.