Share

Pin

Tweet

Send

Share

Send

Sewing such a hat is a pleasure - it requires a minimum of fabric and equipment, and also only a couple of hours of time. And therefore, even a mother very busy with everyday worries can afford to sit down in the evening and sew it, as they say, for her pleasure.

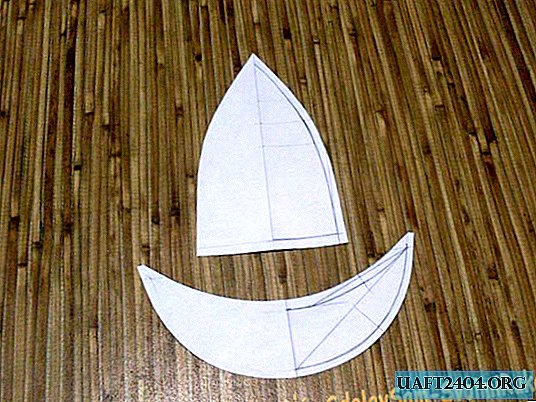

Before you begin, you need to stock up on a pattern of a 6-blade cap. It can be downloaded on one of the sewing sites on the Internet, or you can build it yourself, but it will take a little more time. In any case, it is necessary to select a pattern, taking into account the circumference of the baby's head.

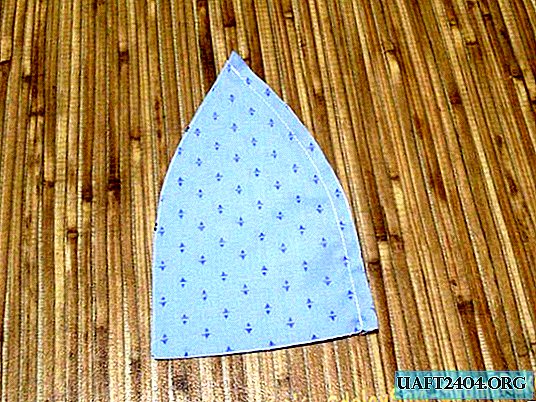

In general, the classic cap includes only 2 main details: the wedge itself, as well as the visor.

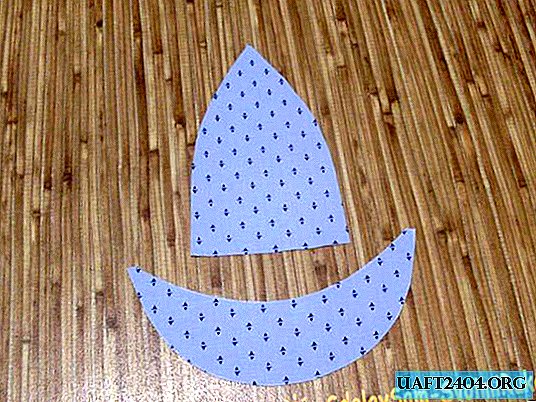

From the pre-ironed cotton fabric, 6 parts of the wedges should be cut out, as well as 2 parts of the visor.

Allowance for seams in all sections should be given no more than 7 mm.

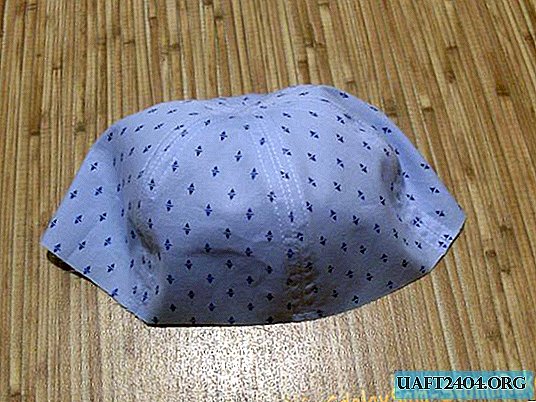

2 parts of the cap should be grinded together along the side sections with a 7 mm wide seam. The details are superimposed one on top of the other face to face.

At the beginning and at the end of the line, it is imperative to put the braces.

Seam allowances for sewing cap parts need to be ironed and stitched close to the line, as shown in the photo.

After laying the finishing stitch, the seam allowances should be cut to a width of 3 mm.

On the seamy side, the seam for grinding the parts of the cap will be closed with an oblique trim. So the product will look neat, will hold its shape and will last a very, very long time without losing appearance.

A cotton slanting inlay, selected in the color of the base material, should be pinned or swept from the wrong side, closing the seam allowances for sewing cap parts.

Then, on the front side, it is necessary to lay two finishing lines, each of which will fix the take-off edge of the inlay. These lines must pass at a distance of 7 mm from the seam of the seaming of the parts of the cap.

After stitching the stitches, the pins or binder must be removed, and the assembly itself neatly ironed from the inside.

Similarly, the third wedge of the cap should be ground.

Then in the same way you need to prepare the second part of the cap, also consisting of three wedges.

Then halves of the cap need to grind together. The seam allowances from the seamy side are closed with an oblique in the same way as the seams of the sewing of its parts.

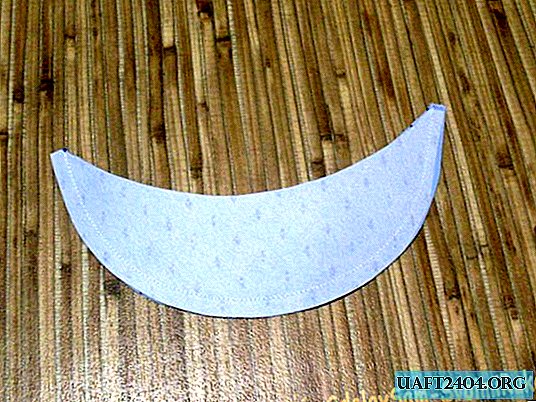

One of the details of the visor should be duplicated with proclameline or non-woven. So he will keep in shape.

Both parts of the visor must be folded facing each other and grind at the outer cut with a 7 mm wide seam.

For convenience and to avoid displacement of the parts relative to each other, they can be stabbed with pins, which must be removed after grinding.

Grinding seam allowance should be cut with scissors, slightly not reaching the line.

Then the seam allowance for turning the visor must be stitched onto the lower (non-duplicated) part of it. The line should extend 1 mm from the seam itself. This operation (the so-called fluffing) will help the visor to keep its shape well.

After this, the visor must be ironed from the inside out. Both layers of fabric should be swept away along the edges along the stitching sections to the cap.

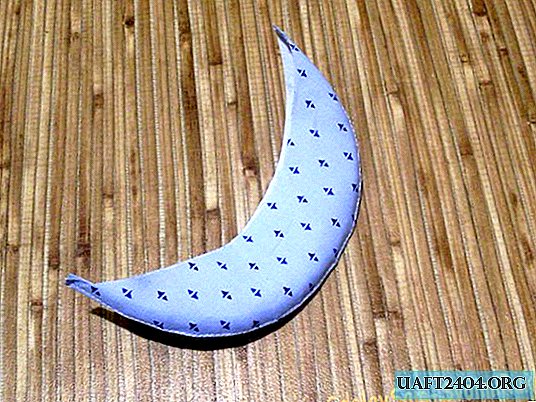

The finished visor must be pinned or swept to the cap, placing it symmetrically with respect to the middle (last sewn) seam.

Then, along the entire perimeter of the cap, you need to grind a slanting inlay. To do this, you need to put it on the cap face to face and sew it "into the groove" (the ironed fold of the inlay).

The ends of the tape must be carefully ground together.

After attaching the beak, the pins securing the visor must be removed.

The margin of the take-off edge of the inlay (also ironed to the wrong side) must be stitched with a seam 1-2 mm wide, as shown in the photo.

The seam allowance for attaching the tape to the cap must be sewn onto the tape. The seam is 1-2 mm.

In the back of the cap, the oblique trim should be swept to the wrong side and secured with a finishing stitch that goes 1-1.2 cm from the seam of its stitching. This will be a drawstring under the elastic, thanks to which the cap will sit well on the baby’s head.

After the operation, the manual auxiliary line must be deleted.

The oblique trim must be ironed on the wrong side of the product. Then it must be fastened with short machine lines at all seams of the sewing together of the parts of the cap, as shown in the photo.

Then you need to insert a narrow linen elastic into the drawstring. Its end faces must be fixed with machine lines.

Summer cap for the baby is completely ready! It's time to get ready for a walk!

Share

Pin

Tweet

Send

Share

Send