Share

Pin

Tweet

Send

Share

Send

I don’t argue, it would be faster to buy a ready-made ultrasonic humidifier, but it turned out for me on spare parts that it came out by itself. In the article I will show how and what I made it of, and in the end, I will tell how I would have made it now, based on the experience of running in now.

In March, an ultrasonic atomizer in a plastic case arrived to me, I specially prepared for the summer, the design was assembled, but once, the level sensor built into the ultrasonic head did not work, and as a result of working on a dry one, the sensor case melted, and in some places burned out, though , I noticed this not immediately - it worked out.

A week ago, an ultrasonic head came to me already in a metal case, which means that I had to disassemble and rebuild the entire structure.

Will need

In stock I had:

- - office bucket with a capacity of 10 liters;

- - 12 volt power supply;

- - an ultrasonic atomizer in a metal case;

- - black mounting box measuring 100 x 60 x 25 mm;

- - any boosting module, I had the Xl6009 module;

- - speed control 12 volts;

- - impeller;

- - power switch, several sockets and plugs to them;

- - improvised little thing appeared in the assembly process;

- - and also - the case from a faulty speed controller - you will see it later.

Visual connection diagram

I had to try to make sure that all this did not look porridge and was convenient for perception.

- - input 12 volts is increased by the module to 22 volts and fed to the ultrasonic atomizer;

- - also, the input 12 volts are supplied to the unit controlling the fan speed;

- - both of them are connected in parallel and are connected to the input jack through a common power switch.

The ready-made speed controller immediately came to me faulty, and as it happens, it was put in a bunch “until better times”, and its case with four convenient mounting holes went into action. You see what happened to the filling. For a while, the current was so high that the wiring leading to the socket on the ultrasound head burned out and melted. However, both modules turned out to be serviceable and it was only necessary to replace the wiring.

At the end of the office basket, I drilled four holes for installing screws to which the control unit was attached, even lower, you see a hole for passing the wire going to the ultrasonic head.

The first option, I collected in a hurry, and such a decision revealed its shortcomings. If you look inside the basket, you can see that the screw heads were corroded.

To get rid of rust, it was necessary to transform it with tampons moistened with a strong solution of edible citric acid

After brushing and drying, the heads were filled with clear acrylic glue from a hardware store.

Fan assembly

It should be completely protected from splashes and after a short deliberation, I decided to use a centrifugal impeller which I glued into a black plastic box on the strips of a double-sided mounting tape based on 1 mm.

Through a smaller hole on the bottom of the box, air is fed into the basket. Please note that the intake hole on the top of the box and the outlet on the bottom will be opposite to each other. Thus, no spray can reach the turbine engine. Along the perimeter of the resulting assembly, I pasted a sealing tape used to seal the openings of the opening plastic windows, and a piece of twisted cord from the plugs at the end was soldered to the turbine itself. Soldered contacts were sealed with hot glue.

Cover assembly

Back side.

The lid of the office bucket, as you know, is equipped with a rotary valve, and it delivered me the most inconvenience.

- - at first, I outlined and made a hole for the exit of water fog;

- - then, I dozed out a rectangular window for the fan assembly;

- - in order to stop the valve, over the entire internal area of the lid, I pasted a foam blank on a waterproof adhesive;

- - the workpiece, so that it does not poison the steam, had to be well moistened with the same glue in several stages;

- - after drying, on an almost water-repellent foam blank, I pasted the blank from the linoleum trim.

In the slice, you can see which sandwich came out:

Cover on the front side. In the drip hole, half of the chocolate egg is inserted. With some effort, it can rotate. I advise you to burn holes in it only on one side, so that the flow of cold steam can be directed away from the fan assembly and the air intake hole.

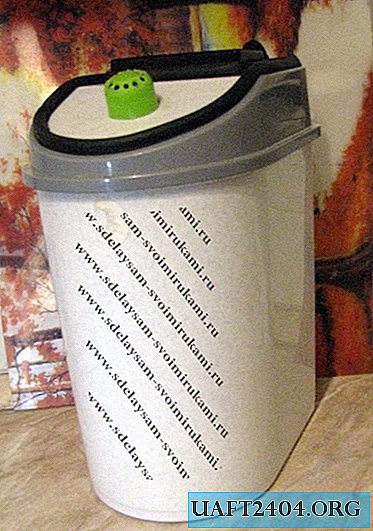

As a result, the general view of the washed office basket without the fan assembly installed is like this.

To give a less collective farm look, I pasted the remaining hermetic tape along the slit contour of the rotating valve.

Float knot

I cut a round float from foamed polyethylene; displays and TVs “put on” a frame of such material.

A yogurt cup is inserted into the float, into which an ultrasonic nebulizer will be inserted.

The first tests immediately showed that the ultrasonic head should be recessed below the surface of the water, to the depth of the phalanx of the finger, but at the same time, individual sprays still flew out of the fountain of fog. Therefore, I had to think about a quencher. It is made of a cylinder cover with mounting foam, and fortunately, it had an eyelet with an opening for the foam tube.

Traces of rust are explained by the fact that instead of nylon cable ties, I used a metal pin, and after soaking in citric acid, during the final assembly, I will begin to use them.

Actually, that's it - the cleaning is finished, then a series of photos with explanations will go, in which you will see the process of final compilation of spare parts.

Behind her, I will share my thoughts on what I would have done differently and the video of the operation of the humidifier assembly.

Electronics node

The wires were soldered. At the same time, on the left, you see the slot for connecting the fan unit.

And the lid is closed. Two lower nests. Right, the output to the ultrasonic head, the left socket is designed to connect an external power supply +12 volts.

Ultrasonic head and float system

I had to cut the standard wire because of its poor flexibility and spliced it with flexible conductors in a silicone sheath. Solder areas were generously sealed with hot glue. And, pay attention - the wire is passed through a silicone cap which closes jars with antibiotics.

You saw a through hole in the office basket, a lid with a wire in its center will be inserted into it, which will serve not only as an obstacle to the exit of fine mist, but also allow you to remove this entire unit without biting the conductors.

But the floating platform had to be completely changed. The metal atomizer was difficult for her and the buoyancy was negative.

I took, as you see the polystyrene foam, I was lucky, it is a dense polystyrene from the polystyrene foam box, 24 mm wide and 100 to 115 mm wide on the sides.

The basket for the ultrasound head also had to be replaced with a whole yogurt cup. The atomizer was pressed firmly into the cup to the bottom, and with a soldering iron, holes were opened for water to enter inside this small container.

You will have to experimentally find out the buoyancy of the platform, but I will say right away - there is no alternative to polystyrene.

Test run

Water is poured into the basket, the ultrasonic unit is lowered to the surface, the plug of the ultrasonic unit through the silicone lid passed through the wall of the office basket. You can also see that along the inner perimeter of the basket, the same sealing cord is glued.

System at medium speed.

The consumption of the system was at maximum fan speeds and with an external power supply of 12V - 1.92A. Without fan 1.72A.

So I change now.

Firstly - the lid, it seems to me that it turned out not quite successfully. Go up to the picture in which I showed the inverted lid. It will be better if you cut a piece of plastic from a single sheet of plastic with the inner edge (step) of the lid. After gluing and checking for sealing, the fan assembly can be placed in the formed place under the rotating valve of the office basket lid. I think that there was enough space for other electronics. Which one?

For example, a humidity sensor. There are modules with humidity sensors combined with a relay, and after calibrating and setting the module to 40% humidity, you can forget about games with a switch. Humidity will always be automatically maintained at the optimum level.

Secondly, a security system. I guess why the previous fog generator in a plastic case burned out. On it (as well as on this one), a capacity sensor is installed in the form of a bracket and probably, the fog generator skewed due to its lightness - the capacity sensor turned out to be in water, and the piezo-membrane turned out to be a part in the air, which led to overheating of the entire head. Compact capacitance sensors are produced on the TTP223 chip, it can and should be glued at a minimum level of water in the basket from the outside, which is guaranteed that this ultrasonic head, albeit heavy, would still be in the water. The sensor itself, can control the boost module, the boost module has a controlled input.

Thirdly, a boost module can be cheaper, not necessarily the one I used - there was nothing else at hand.

The approximate cost of the entire set:

- - office basket - 2.5 dollars.

- - Ultrasonic atomizer - $ 5.6.

- - Xl6009 step-up module, which may be different - 0.80 dollars.

- - turbine - 1.43 dollars.

- - black box 100x60x25 mm - 1.08 dollars.

- - ready-made speed controller - 1.32 dollars.

Total: approximately $ 12.

Everything else I had was available. I believe that this homemade product, which does not claim to be the center of the festive table as a samovar, nevertheless, has all the necessary consumer qualities, which for the money, most likely cannot be found in the finished version.

Thanks for your attention.

Ruslan.

Watch the video of work

Share

Pin

Tweet

Send

Share

Send