Share

Pin

Tweet

Send

Share

Send

Not so long ago, I gave light how to make a handle for a knife from cold welding. Some "critics" asked - why sawdust? I answer; I used sawdust for a larger volume, as well as to reduce the weight of the handle, and to save cold welding. A monolithic handle from pure cold welding would weigh pretty decently, and would break at the first, more or less, a strong load (pressure) on it, for example, when elementary cutting a branch from a tree. A second glue so that the sawdust mixed with glue is grabbed to the knife pin.

However, this hilt got tired of me pretty quickly. And I decided to follow the advice of one of our esteemed commentators; that if you put the blade pin in a clean glue, without impurities of sawdust and second glue. But in order for the knife to have a stable and durable handle, I decided not to risk it, and apply borders in the form of a body for cold welding. So that she does not burst when pressed, at the most inopportune moment. For one I’ll tell you how to soften superglue.

Will need

- A piece of metal-plastic tube (diameter 20 mm)

- Cold welding.

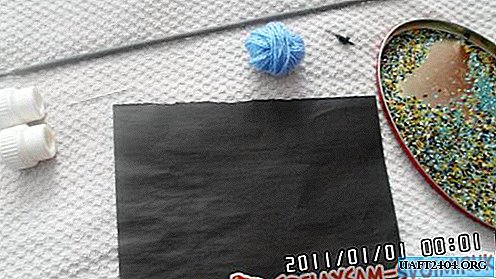

- Self-adhesive film (with any texture you like).

- Scissors.

- Stationery knife.

- Lace from shoes.

- Mallet.

Manufacture

So, in order to soften the second glue, you need to drop acetone mixed with vinegar in it in a one to one ratio, wait half an hour until the acetone-vinegar liquid penetrates into all the cavities and air bubbles that formed during gluing and corrode the glue. Next, lower the product into a soap solution consisting of a dishwashing detergent Comet (a full ten cubic syringe) and a teaspoon of soda diluted in a glass of water. After the glue softens, pull the blade out of the handle.

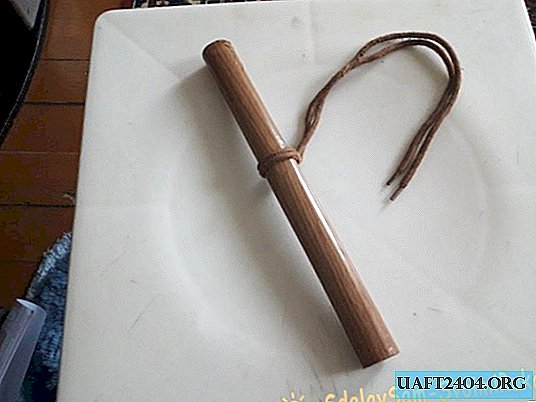

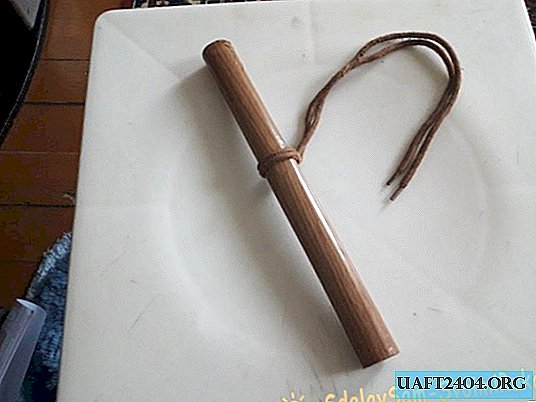

The handle can be made from anything ... from wood, from plastic, from plexiglass ... But if your blade is long and thin, it is best to perform it in the form of "Tan then." This form of knife is universal. It is suitable for any purpose. From plunging the wiring braid to peeling potatoes. And, moreover, a lot of effort is not required for this. It takes only a little patience while the "cold welding" glue dries.

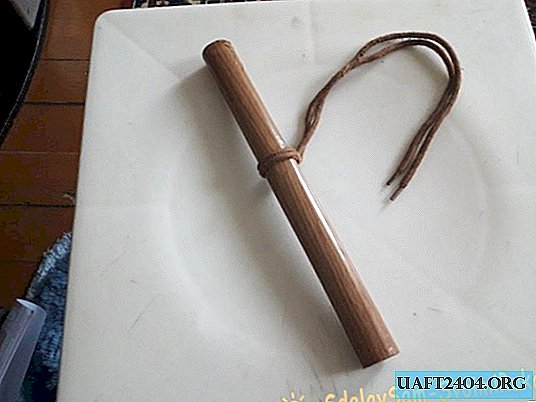

First, prepare the future cover. To do this, we need a metal-plastic tube. We measure the distance of the length of the blade, cut off the desired piece. Now the hilt. Take a piece of metal-plastic pipe in your palm and mark with a marker a distance convenient for you. We flatten the future handle and cover to an oval shape with a wooden mallet. Next, we stir the glue "cold welding" (you will need the whole piece that will be in the tube), wrap the knife pin with it and immediately put it in a pre-prepared tube for the handle.

We make a plug from the same glue, which we install on the other side.

Now let's take care of the scabbard. We hammer the scabbard tube with glue, lubricate the blade of the knife with gun oil (you can use regular vegetable oil!) And stick the knife into the case. We install it so that the handle and cover are like a continuation of each other. We wait until it dries.

The only minus of this variation is that the knife can be returned to the case only in a certain position. It remains only to paste over all this with an adhesive film. At first, I wanted to apply a black film, but after thinking, I decided that the texture of the wood would be more interesting.

Share

Pin

Tweet

Send

Share

Send