This review shows a detailed manufacturing and installation process for sliding metal gates. This is the best option for a private house.

The first step is to dig a trench under the future foundation for the sliding gate.

From scraps of boards and bars, the author makes up a formwork with holes for studs.

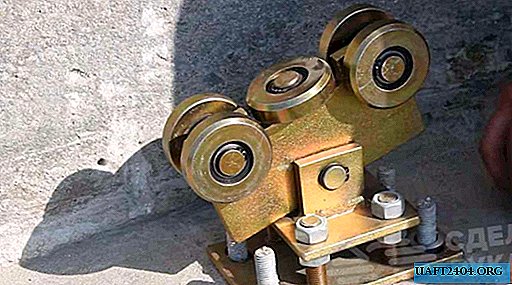

The studs themselves are welded to the reinforcement bars. They are needed for fixing roller carriages.

After that, you can begin to fill the foundation. For convenience, the author installed a concrete mixer next to the trench.

The main stages of work

At the next stage, the author proceeds to manufacture the gate. To do this, he uses profile pipes.

The lower part of the frame is made of a square C-shaped profile and is the gate console (guide beam, inside which the rollers are located).

The welded gate frame will need to be primed and then painted. This is convenient to do with a spray gun.

Next, we attach two roller carriages to the foundation. The platform on which they are placed on the studs and fixed with nuts.

At the last stage, it remains only to install the gate. Remember to lubricate the bearings before doing so.

For more information on how to make sliding gates for a private house with your own hands, see the video on the website.