In this review, the author shows how to make the most simple grinder on the basis of a small grinder (angle grinder). This device is useful for grinding pipes and round blanks made of metal, as well as holders made of wood - for garden tools.

For the manufacture of homemade products you will need a piece of a round pipe, profile pipes, a bolt with a nut, metal plates and a spring.

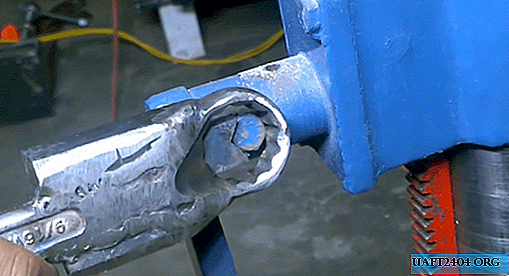

First of all, cut a piece from a round pipe. We cut out a part of the wall, and weld two nuts at the edges into which we screw a bolt. The result was a homemade clamp for angle grinders.

The main stages of work

At the next stage, we cut two pieces of the profile pipe: long and short. On one side of the blanks we make a saddle, and then we weld them to the clamp.

The author welds two pieces of the plate to a short section of the profile. Then he cuts off another piece of the profile pipe. Holes must be drilled in the profile and plates so that they can be joined together. As a result, we get a movable connection.

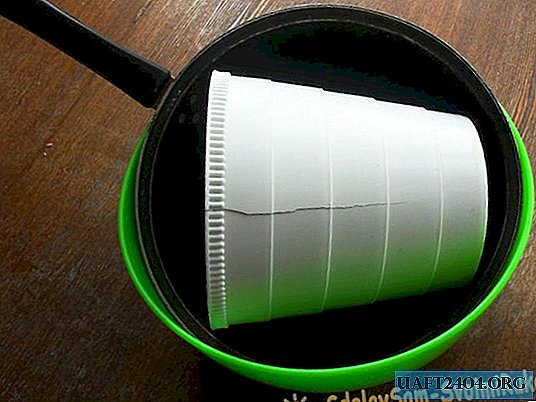

Next, on a lathe, it will be necessary to carve three rollers with sides for the sanding belt. If there is no lathe, you can order the manufacture of these parts to a turner.

After that, we install the manufactured rollers (two on the edges of the profile pipes and one is attached to the shaft of the grinder) and fix the clamp on the grinder gear housing.

To a short and long profile pipe, you need to weld small metal plates with drilled holes. They are necessary for securing the spring.

Then glue the sanding belt of the right size, and put it on the rollers. For details on how to make a simple grinder based on a grinder for grinding, see this video.