Very often, many masters are faced with a problem such as imbalance in the grinding wheel. The "symptoms" of this phenomenon in most cases are of the same type - when starting the engine and especially when stopping, the emery machine starts to jump strongly on the table.

Sometimes it even comes to the fact that half of the garage or workshop is shaking. This is when the machine itself is fixed to the table with bolts. And if you don’t fix it, then when you stop it, it can easily “gallop” to the floor.

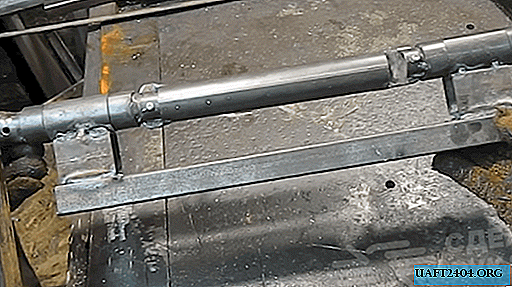

How to solve the problem with the imbalance of the grinding wheel? This problem is resolved on overweight machines or special balancing machines. But in a garage and a home workshop, you can use a different, more affordable and simple way.

Do balancing the grinding wheel with our own hands

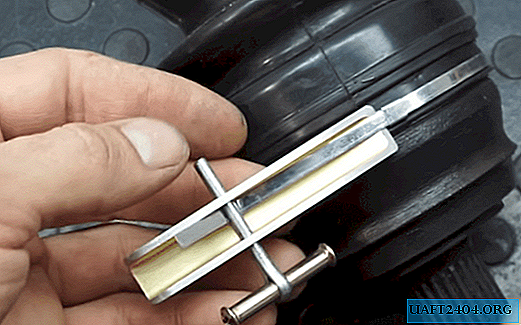

First of all, it will be necessary to carve a suitable fluoroplastic sleeve. It should fit tight enough into the hole in the grinding wheel, and sit like a glove.

Next, we put a paper gasket on the grinding wheel, then a metal circle 2 mm thick. Note that the thickness of the circle depends on the size of the imbalance itself. If the imbalance is large, then the circle of metal can be taken thicker.

Then we put a regular washer, an ordinary washer, and clamp everything with a nut by hand. Then moving the metal wheel, you can balance the grinding wheel as necessary for comfortable work.

For details on how in the home workshop or in the garage you can independently eliminate the imbalance of the grinding wheel, see the video on the site.