When installing a water pipe made of low-pressure polyethylene, special couplings of various diameters are used. If couplings with a diameter of up to 50 mm can be tightened with a gas wrench, then a larger diameter must be tightened with special wrenches.

In this review, we will tell you how to make such a key from various types of metal. For its manufacture, sheet metal, a square bar, a bolt, metalwork and drilling tools, gas welding equipment will be needed.

To begin, prepare the cap part for the key. Draw a semicircular workpiece and cut out half of it (a quarter of the circle). We drill a hole from one edge slightly larger than the diameter of the connecting bolt. Put the workpiece aside and proceed to the manufacture of the handle.

The main stages of work

At the next stage, we take a bar and heat it from one end (observe safety precautions and protective measures when working with gas welding equipment). We give it exactly the same circle as the cap part.

Next, straighten the handle to a suitable angle. We proceed to drilling holes in the curved part of the bar. To do this, first drill a through hole slightly smaller than the diameter of the connecting bolt.

Then we saw the butt end of the rod perpendicularly to the hole to a depth slightly greater than the hole drilled. We drill one of the holes to the desired diameter (as on the cap part).

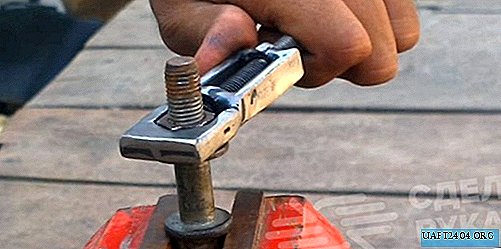

We cut the threads in a small hole and connect all the parts together by means of a bolted connection. Cut off the excess bolt (if any).

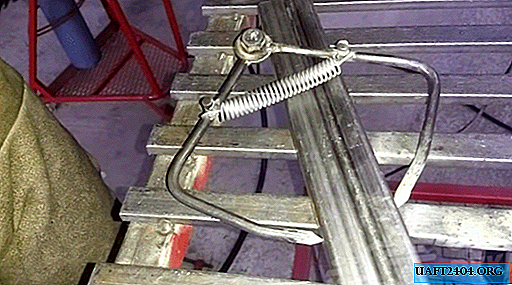

Finally, you can weld to the cap part of the hook blade from a piece of sheet metal. We trim to the desired size and clean all welds.

We will paint in the color we need and the homemade wrench for tightening the PND couplings is ready. See the video below for manufacturing details.