If you urgently needed ventilation grilles, blinds (for example, when making the case of a device or to temporarily close a “bare” ventilation hole in the garage), you can do it yourself.

To do this, you need a piece of sheet metal of the right size and a thickness of 0.5-0.6 mm, a home-made matrix template of 2 pieces of plywood, a “punch” in the form of a scapula (also made of plywood).

The dimensions of the “punch” can be different, depending on how long the slotted holes in the sheet of metal should be. For example, in this case, the width of the blade is 10 cm, and the length with the handle is 15 cm. The thickness of the plywood is 20 mm.

The main stages of work

A matrix is made from two pieces of plywood or a board. One of the parts is attached to the table with screws. The width of the slot should be 2 cm greater than the width of the "punch".

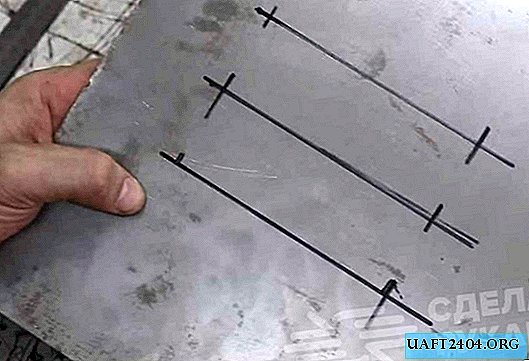

At the next stage, it is necessary to cut the blank from sheet metal, and make marking with a marker. The distance between the lines is 4 mm. In total, the master drew three lines, but there may be more if necessary.

According to the markup, the master with the help of a grinder makes three slots 11 cm long. The surface of the metal must be cleaned so that there are no burrs.

Then the workpiece is pressed to the matrix with a small plank, and with the help of a hammer and a “punch” the master makes slotted holes. Here it is important not to rush so that all the holes are neat.

For details on how to make sheet metal grilles yourself, see the video on the website.