If you often go out with friends to nature (for a picnic or fishing), then a folding barbecue grill will definitely come in handy. You can do it yourself with an ordinary freon cylinder. Thanks to the compact size, such a homemade product can easily fit in the trunk of a car.

The main stages of work

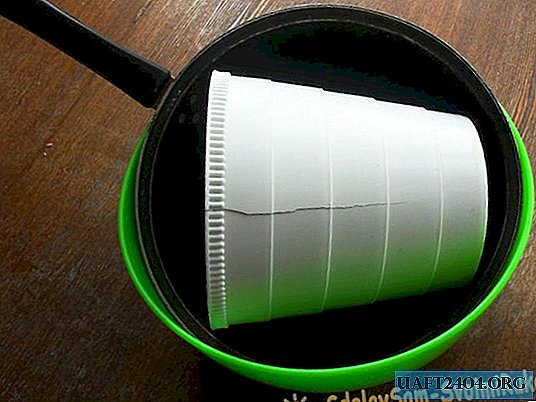

First of all, you need to remove the handles on the cylinder, having drilled contact welding with an electric drill, and cut off the valve with a grinder. Next, you need to cut the metal case into two halves - for this, using a marker and a building level, draw a straight line, then paste masking tape along the contour, markup and cut the balloon with a grinder.

At the ends of the case we do not cut a little, so that loops can be installed. If the workshop does not have a lathe, then the loop can be made in an alternative way. To do this, you will need a bolt and extended nuts. We tighten the nut until it stops, after which we cut off the protruding threaded part.

The bolt stem must be cut along the length of the second nut, which must first be drilled with a drill with a diameter of 8 mm. The result is a simple but quite nice loop that is ideal for attaching a barbecue grill cover. At the next stage, we weld two loops and cut the remainder of the freon cylinder with a grinder.

Drilling holes

We make markings on the lower half of the body (on the back side) and drill four holes for skewers at the same distance from each other. On the front side you need to make four slots. Then we drill the air holes in two rows every 4 cm, departing from the edge of about 5-6 cm.

Of the four elongated nuts, cut at an angle of 40 degrees, we make the mount for the legs and weld them to the body. The legs themselves are made of reinforcement with a diameter of 10 mm. The last thing you do is a pen that attaches to the lid. The detailed process of assembling a folding barbecue grill, see the video on the site.