Keyless clamps are used when carrying out large volumes of work, when fast fixing of wooden workpieces during gluing is required. Here are just factory models are not cheap. Therefore, if you want to save money, you can make such clamps with your own hands - from a conventional gun for sealant.

This homemade product can be used in the process of gluing wooden workpieces, as well as in the repair of cabinet furniture, shoes, etc. The clamping jaws can be made of two rectangular bars. Still need a couple of screws and wood glue. In general, the cost of manufacturing a homemade clamp is minimal, so everyone can do it.

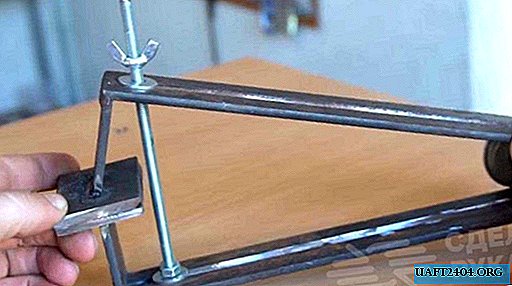

Joiner's clamp: the main stages of work

First of all, it is necessary to securely fix the fixed sponge - for this, in the wooden block we make slots for the metal pusher (rod) and the upper part of the handle of the gun for sealant. You can choose a groove of suitable sizes on a circular saw or using a drill, then finalizing the inner walls of the chisel.

When the fixed sponge is ready, we attach it to the gun body on ordinary screws, after having previously drilled a couple of holes. Then we proceed to the manufacture of a movable sponge. In the second wooden block, you need to drill a hole for the curved end of the rod.

That, in fact, is all the work. To quickly clamp the workpiece with a clamp, you only need to press the trigger of the sealant gun several times. And loosening it is even easier. For a detailed assembly process of a homemade clamp, see the video on the site. Write what you think about this device.