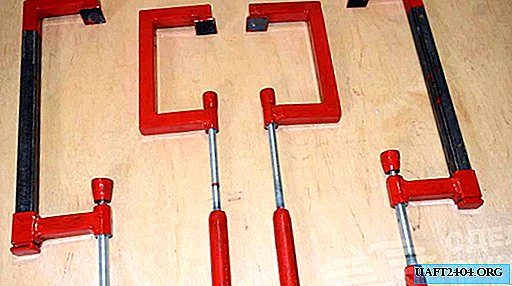

In any home workshop, a clamp can not be dispensed with, especially when it is necessary to glue wood blanks or securely fix metal parts. If you do not want to spend money on the purchase of factory clamps, the prices of which are often overpriced, then you can do them yourself.

This will require the most popular and inexpensive material - a professional pipe. And for a start, you need to cut the lengths of the profile necessary for the length.

Moreover, the edges of those blanks that will dock with each other will need to be cut at an angle. Also for homemade work you will need pieces of round pipes, studs or long bolts and nuts (regular and elongated).

The main stages of work

At the next stage, a preliminary fitting of the clamp parts is carried out and their subsequent connection by welding. It is better to use rutile-coated electrodes with a diameter of 2.5-3 mm, since the metal is thin.

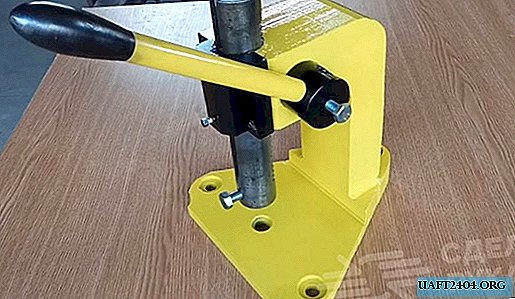

If desired, you can make several options for the F-shaped clamp. Profile - the material is not scarce, so if you wish, you can equip the garage or workshop "to the eyeballs."

Well, then it remains only to weld all the prepared parts together. The seams must be cleaned with a grinder, and the finished clamps must be painted. As you can see, there is nothing complicated about this.

For more information on how to make simple home-made F-shaped clamps from a professional pipe, we recommend that you watch in the video on our website. Write in the comments what you think about this idea.